HYPERNOVA ULTRA-S BURR SET

A new geometry which grinds faster and with a tighter distribution grouping for espresso and a higher percentage of particles within the 50-600 micron range.

Silky body, increased clarity and high definition of flavour, improved balance and a high acidity.

440 Stainless Steel Base material improves edge hardness to HRC65.

An extra process is added to polish the burr on a micron level to remove any tiny imperfections and an added dual coating titanium and thermal plasma is added to create an edge hardness of HRC67.

GRIND CONSISTENCY

The Hypernova ULTRA-S has an updated geometry and pre-crushing teeth to deal with lighter roasts and denser variaties of coffee.

A high percentage of consistency comes from the geometry as well as the higher draw point in relation to the outer burr which contributes to more pre-crushing and consistency overall.

The plasma coating will also offer an improvement to the consistency of particle sizes.

DURABILITY & HEAT SINKING

The plasma coated burrs will have an increase in durability and also heat resistance. The burrs will stay cooler on the cutting edge during grinding and as a result this will impact the overall durability and sharpness of the cutting edge.

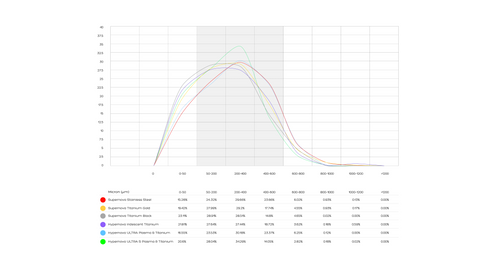

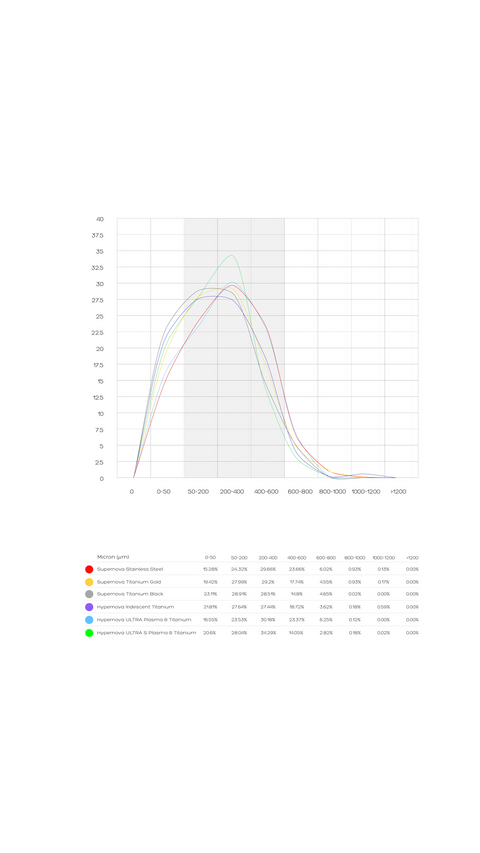

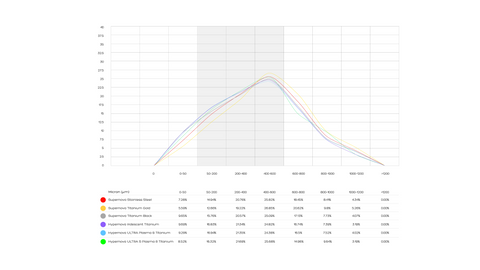

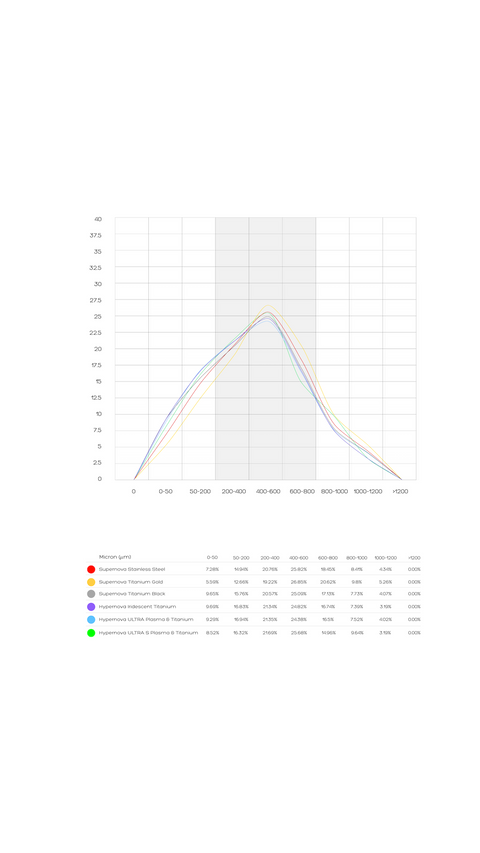

PARTICLE DISTRIBUTION

The grinding range of the titanium coated burr vs the regular stainless steel will be improved at the top end of finer particle sizes.

The ULTRA-S has a much higher peak of its range of consistency with an ability to grind a higher percentage of fine particle.